Definition

Ultra pure precision steel refers to a steel grade with low content of other impurity elements in addition to strict control of non-metallic inclusions in the steel. These impurity elements generally include oxygen, carbon, sulfur, phosphorus, nitrogen, as well as trace elements such as lead (Pb), arsenic (As), antimony (Sb), bismuth (Bi), copper (Cu), tin (Sn), etc. These elements are difficult to remove during the steelmaking process and may accumulate in the steel as scrap steel is continuously recycled, leading to increasingly prominent harmful effects.

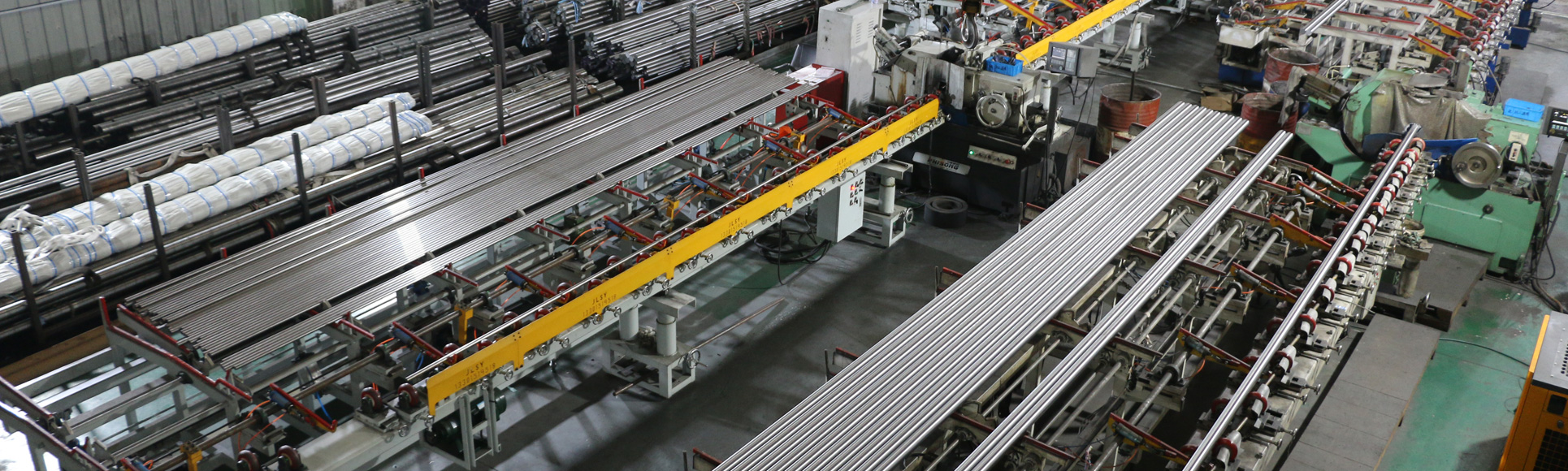

Production process

The production process of ultra pure steel mainly includes the "three de" pretreatment process of molten iron and the refining process of molten steel. Among them, the "three removal" process of molten iron mainly aims at desilication, desulfurization, and dephosphorization, and is treated through reactors such as converters. The refining process of molten steel relies on technical means such as converter dephosphorization and deep dephosphorization of steel ladle powder spraying to further remove impurity elements and non-metallic inclusions in the steel.

Characteristic

High strength: As a type of medium carbon steel or alloy steel, XH45 may have moderate strength and hardness, making it suitable for manufacturing equipment and components that need to withstand certain loads and pressures.

Machinability: Ultra pure precision steel usually has good malleability and weldability, making it easy to perform cold and hot cutting and welding operations.

Corrosion resistance: Due to strict control of impurity elements and non-metallic inclusions in ultra pure steel, its corrosion resistance is usually good.

Application area

Chemical pressure vessels, such as storage tanks, reaction vessels, etc., are equipment that needs to withstand high pressure, high temperature, and corrosive media.

Pipeline system: A pipeline system that transports various chemical media, requiring steel to have good corrosion resistance and processability.

Mechanical components: such as bearings, gears, connecting rods, etc., which need to withstand certain loads and wear.

Aerospace: a field that requires high material performance, the high strength and good corrosion resistance of ultra pure precision steel make it a potential choice.

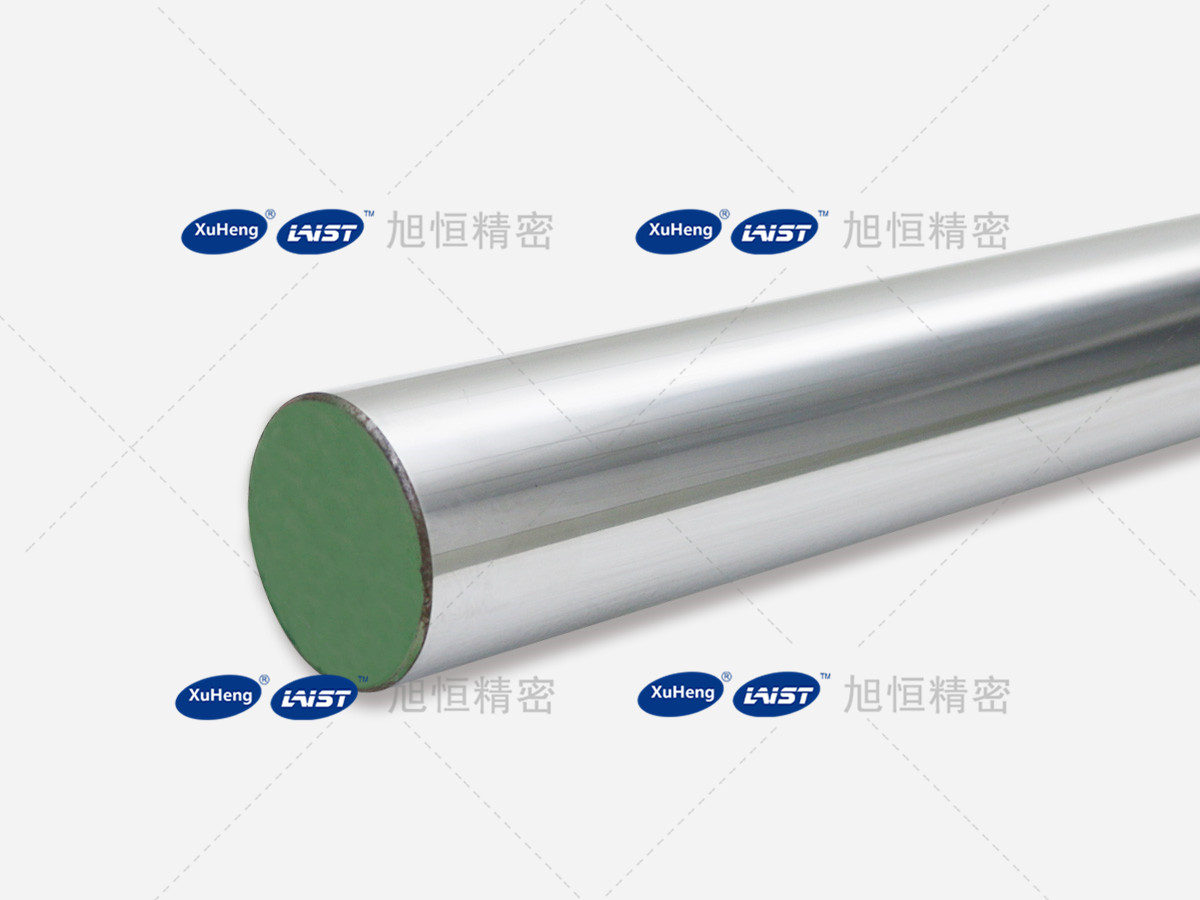

Position:Home > PRODUCTS >XH45 Ultra pure steel

Position:Home > PRODUCTS >XH45 Ultra pure steel