Hollow rod processing is a process involving multiple materials and technologies. The following is a detailed analysis of hollow rod processing:

Processing overview

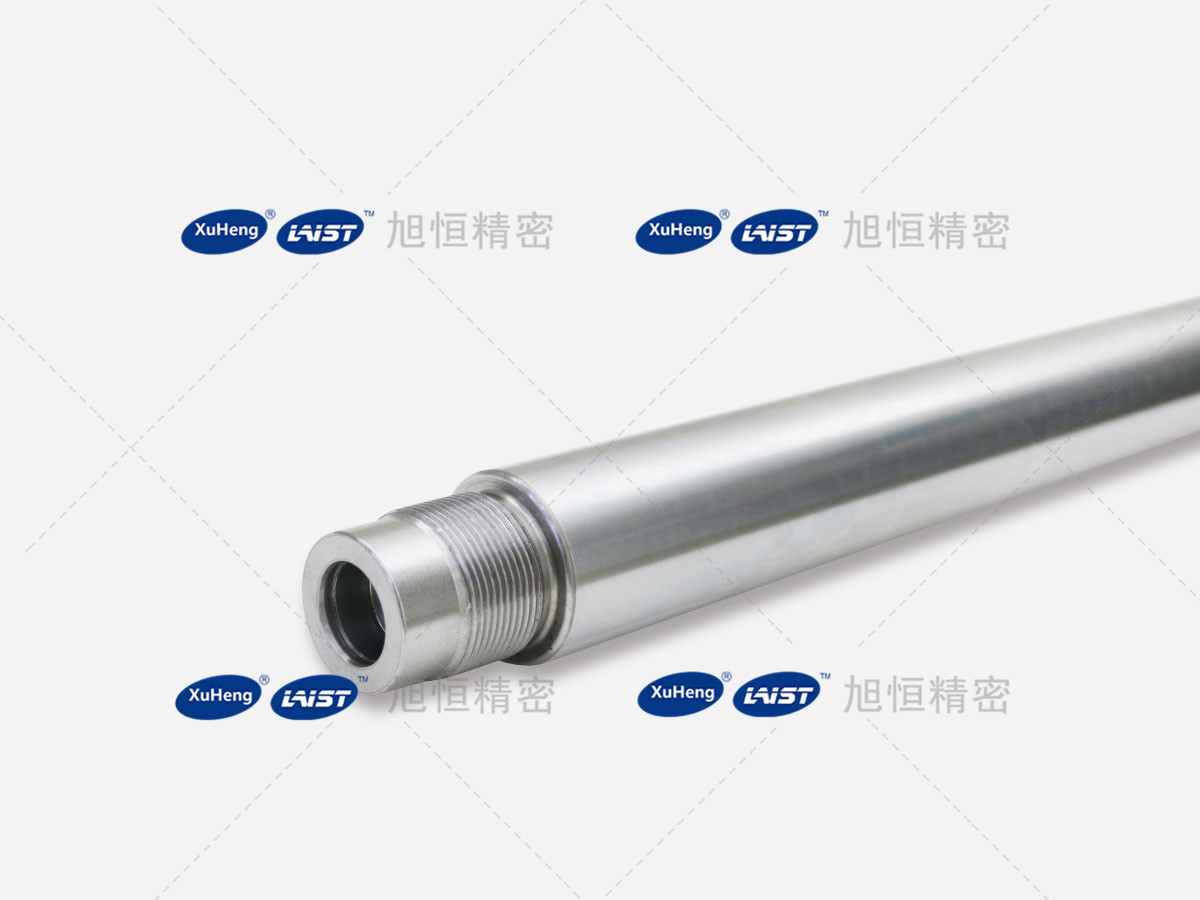

Hollow rods, such as hollow Chrome Rods, are important mechanical components used in various hydraulic and pneumatic transmission systems, as well as in engineering machinery, agricultural machinery, ships, aerospace and other fields. In order to meet the market's demand for high-quality hollow rods, many professional processing plants have emerged. These processing plants provide excellent hollow rod products for many industries with professional production equipment, exquisite craftsmanship and strict quality management.

Processing materials

There are various materials for processing hollow rods, including but not limited to stainless steel, carbon steel, alloy steel, carbon fiber, etc. Different materials have different physical and chemical properties, so different processes and techniques need to be adopted during the processing. For example, carbon fiber materials are used in fields such as sports equipment due to their lightweight, high strength, and corrosion resistance. However, special equipment and processes are required during the processing to ensure product quality and performance.

Processing technology

Material preparation: Select suitable raw materials based on customer needs and product design requirements, and perform necessary preprocessing such as cutting, cleaning, etc.

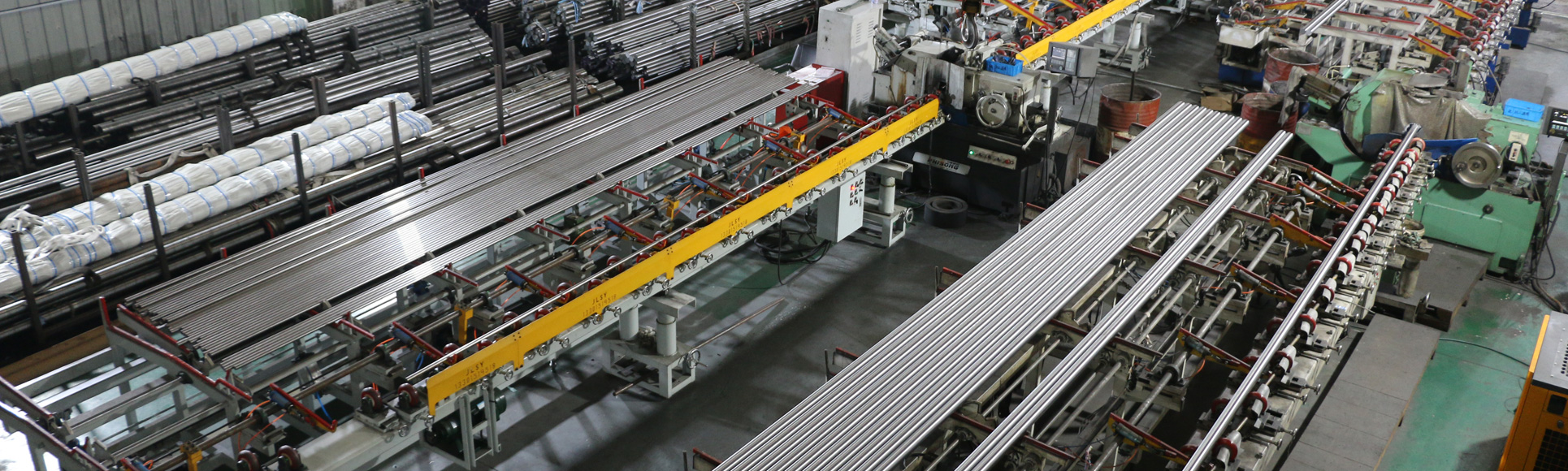

Processing equipment: Professional CNC machine tools, high-precision grinding machines and other equipment are used to ensure product dimensional accuracy and surface quality. Meanwhile, select appropriate cutting tools and fixtures based on material characteristics and processing requirements.

Processing process: including multiple processes such as turning, milling, grinding, drilling, tapping, etc. During the processing, it is necessary to strictly control the processing parameters and process flow to ensure the quality and performance of the product.

Quality inspection: Advanced testing equipment and methods are used to comprehensively inspect the size, appearance, performance, and other aspects of the product. Only after passing the inspection can packaging and transportation be carried out.

In summary, hollow rod processing is a process involving multiple materials and technologies, requiring professional processing manufacturers, production equipment, and technical support. With the advancement of technology and the continuous development of the market, the hollow rod processing industry will continue to innovate and develop, providing better products and services for various industries.

Position:Home > PRODUCTS >Chrome Rod

Position:Home > PRODUCTS >Chrome Rod